EntroMFR

Quản trị toàn diện doanh nghiệp Sản xuất

Tại sao phải dùng Nhiều Phần Mềm Rời Rạc khi Một Hệ thống Quản lý Toàn bộ?

EntroMFR tích hợp toàn diện. Kiểm soát toàn diện. Mọi thứ cần cho một doanh nghiệp sản xuất.

Quản trị toàn diện doanh nghiệp

Hợp lý hóa các quy trình nhân sự của bạn từ tuyển dụng và hội nhập đến theo dõi hiệu suất với EntroHRM

Những cơn ĐAU ĐẦU mà nhà lãnh đạo phải chịu

EntroMFR Giúp chủ doanh nghiệp ĐÁNH BAY cơn ĐAU ĐẦU

EntroMFR - Ưu việt cho cả doanh nghiệp

Với Doanh nghiệp

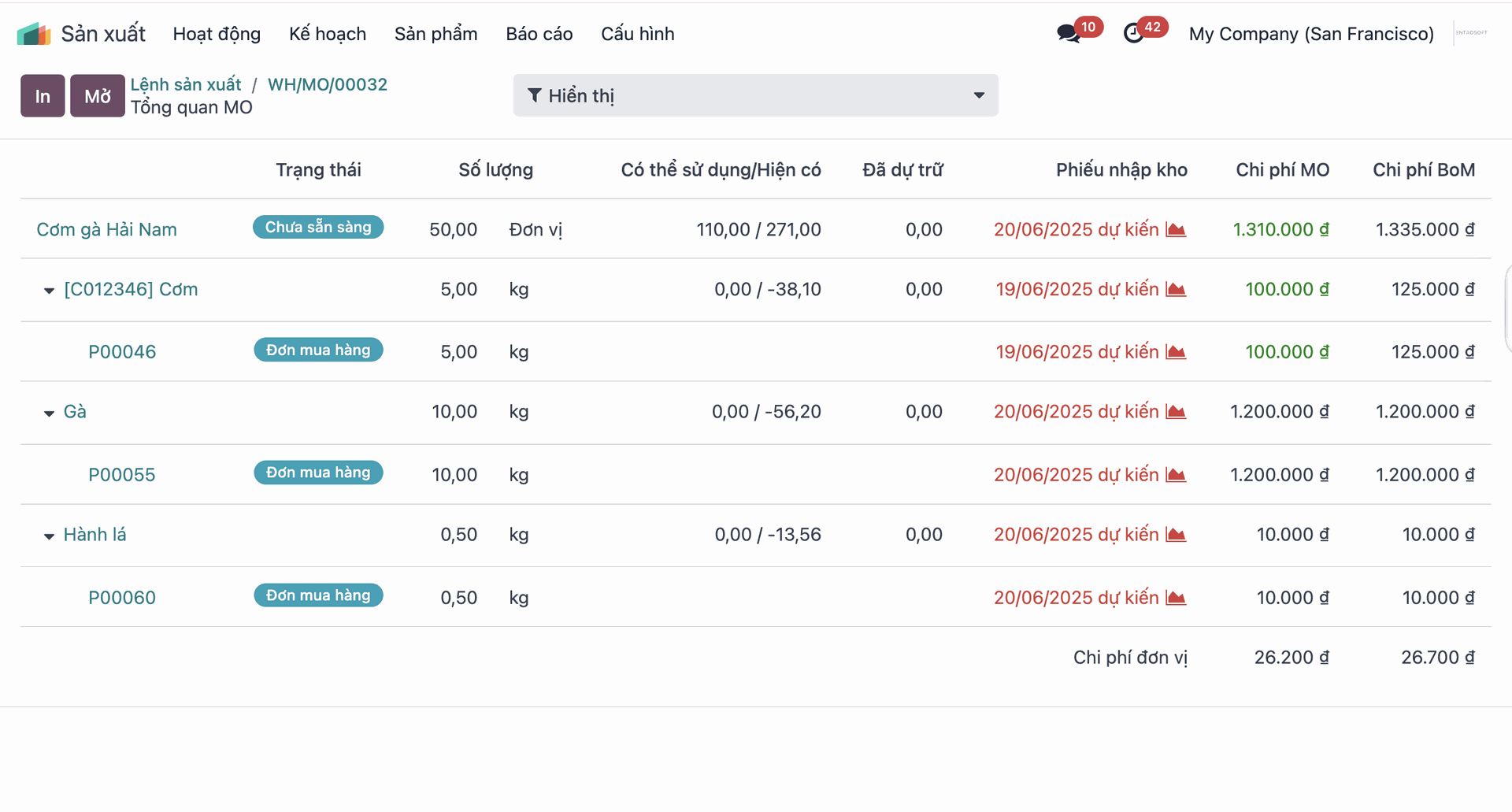

- Chuẩn hóa quy trình: Tinh gọn bộ máy quản lý.

- Tập trung nguồn lực: Ưu tiên hoạt động then chốt.

- Môi trường hiện đại: Tăng hiệu suất, giảm chi phí.

- Gia tăng lợi nhuận: Tối ưu vận hành doanh nghiệp.

- Nâng cao uy tín: Xây dựng hình ảnh chuyên nghiệp.

Với CEO/Ban lãnh đạo

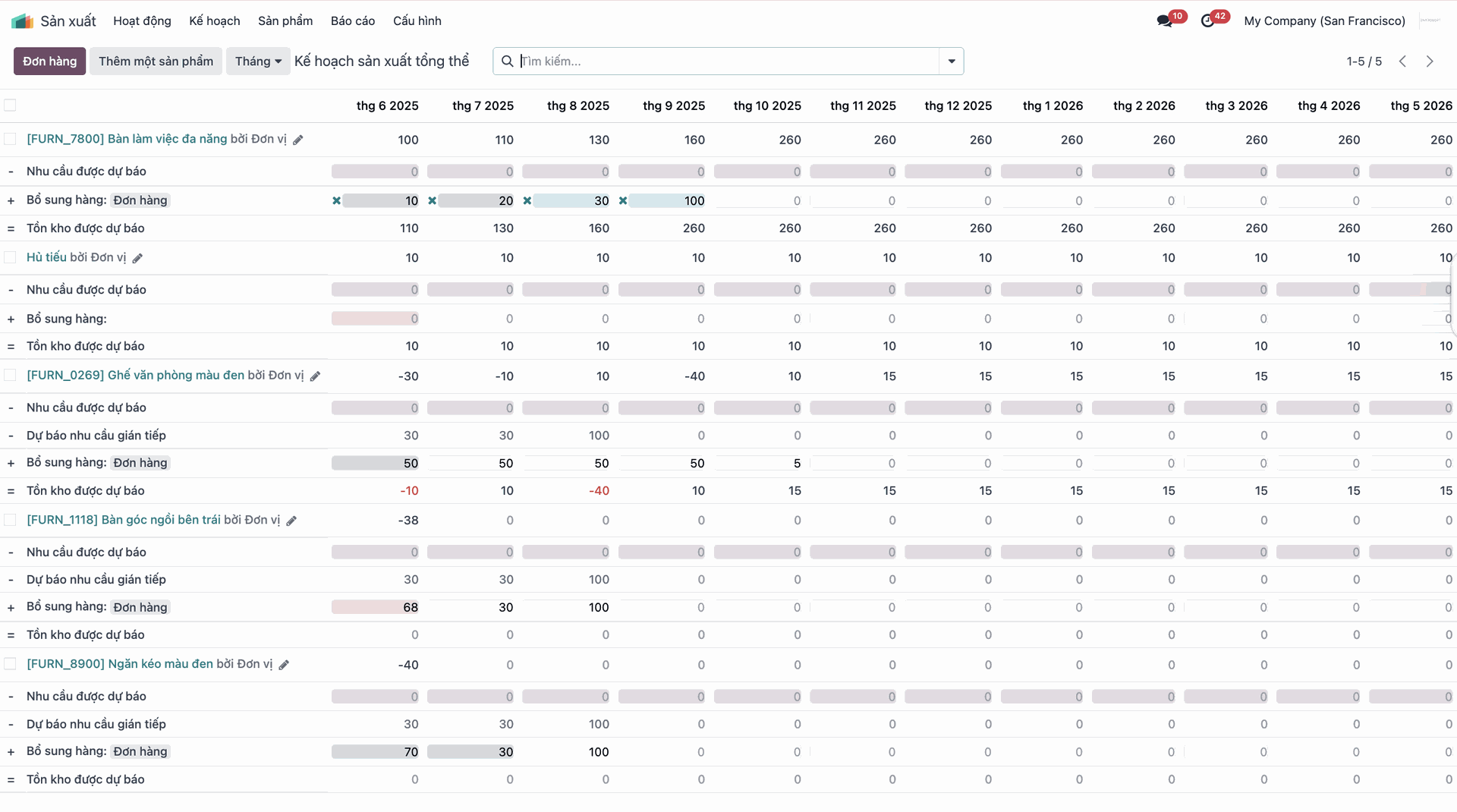

- Theo dõi realtime: Dữ liệu chính xác, cập nhật liên tục.

- Xử lý nhanh chóng: Tăng tốc phê duyệt các cấp.

- Quy trình liền mạch: Quản lý logic, hiệu quả.

- Chiến lược phát triển: Lập kế hoạch dài hạn cho doanh nghiệp.

Với Team lead

- Phân công rõ ràng: Giao nhiệm vụ cụ thể cho nhóm/cá nhân.

- Giám sát tiến độ: Theo dõi chặt chẽ quá trình làm việc.

- Đánh giá hiệu suất: Đo lường hiệu quả nhân sự.

- Xử lý sự cố: Giải quyết vấn đề phát sinh kịp thời.

- Báo cáo & đề xuất: Cập nhật kết quả, đề ra phương án phát triển.

Với Nhân viên

- Rõ ràng nhiệm vụ: Hiểu rõ công việc được giao.

- Bám sát kế hoạch: Làm việc có định hướng.

- Ghi nhận đóng góp: Đảm bảo phúc lợi thỏa đáng.

- Phát triển chuyên môn: Nâng cao kỹ năng, hiệu suất.

- Tăng sự hài lòng: Cải thiện trải nghiệm công việc.